Lack of project visibility, information gaps and poor coordination between various MEPF disciplines lead to faulty installation of MEPF components, project delays, and cost overruns.

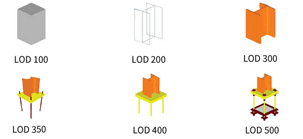

MEP BIM experts at HitechDigital convert your 2D drawings into information-rich 3D BIM models to ease onsite installation through better detailing, increased visibility, and higher stakeholder coordination. By integrating Revit MEP models with architectural and structural models, we identify, inspect, report and eliminate soft and hard clashes. Our MEP coordination services ensure error-free onsite installation and reduce rework. As a further quality check, we run each clash-free coordinated BIM model through a series of validation processes to ensure technical integrity and content accuracy of the model.

Our teams specialize in assembly and piping spool drawings for prefab and installation, conversion of schematic drawings to 3D models, advanced Revit MEP content creation and BIM Project/Template setup for MEP systems.

HitechDigital’s track record of successfully executing 300+ MEPF projects of varying complexities for residential and commercial sectors across 50+ countries is built on strong expertise and domain knowledge. We automate repetitive MEP tasks and accelerate model creation through customized visual scripting and Dynamo backed automated BIM workflows. Our MEP BIM modeling services, tailored to meet specific project and client requirements, are compliant with global standards including Cobie, NBS, RIBA, and ISO 19650.

Clash-free 3D MEPF Models

Coordinated 3D MEPF BIM models resolve conflicts, reduce iterations and enable seamless onsite installation.

Precise Quantity Takeoffs & Estimates

Improve bidding accuracy with precise quantity take-off, scheduling and cost estimation of MEPF systems.

Reduced Change Orders

Visualization into the project at pre-constructions stage reduces change orders to save on project cost and time.

Better Onsite Planning & Safety

Clash-free 3D MEP models improve spatial planning and component location for better onsite safety.

Enhance MEP project design and construction with data-driven solutions for effective construction

Talk to our MEP experts now →

Our mechanical BIM services include stable coordination about the given structure based on clash-free 3D BIM modeling and design validation.

– CEO, Project Management Solutions, Saudi Arabia

We offer 3D MEP modeling and electrical BIM services to electrical contractors to achieve complete connectivity between various trades and BIM electrical design services as per global standards.

– Building Contractor, USA

We provide plumbing contractors with high-quality plumbing BIM design and quick turnaround times for deliverables like water pipes, drainage systems, gas piping and drawings, etc.

– Architectural Firm Owner for Hotels & Hospitality, USA

We assist fire safety contractors and subcontractors to create visual security frameworks via 3D BIM models, design codes and firefighting systems to ensure smooth and hazard-free installation and operation of fire systems.

– Architectural Planning and Designing Firm, India

95% recurring clients and partnerships with industry leaders reflect our commitment to customers – their growth, their satisfaction.

3,100+

Satisfied Clients50+

Countries Served5,000+

Projects Completed1,000+

ProfessionalsBachal represents HitechDigital in North America, and helps client and our production teams collaborate effectively on projects and partnership initiatives.